WeighBridge

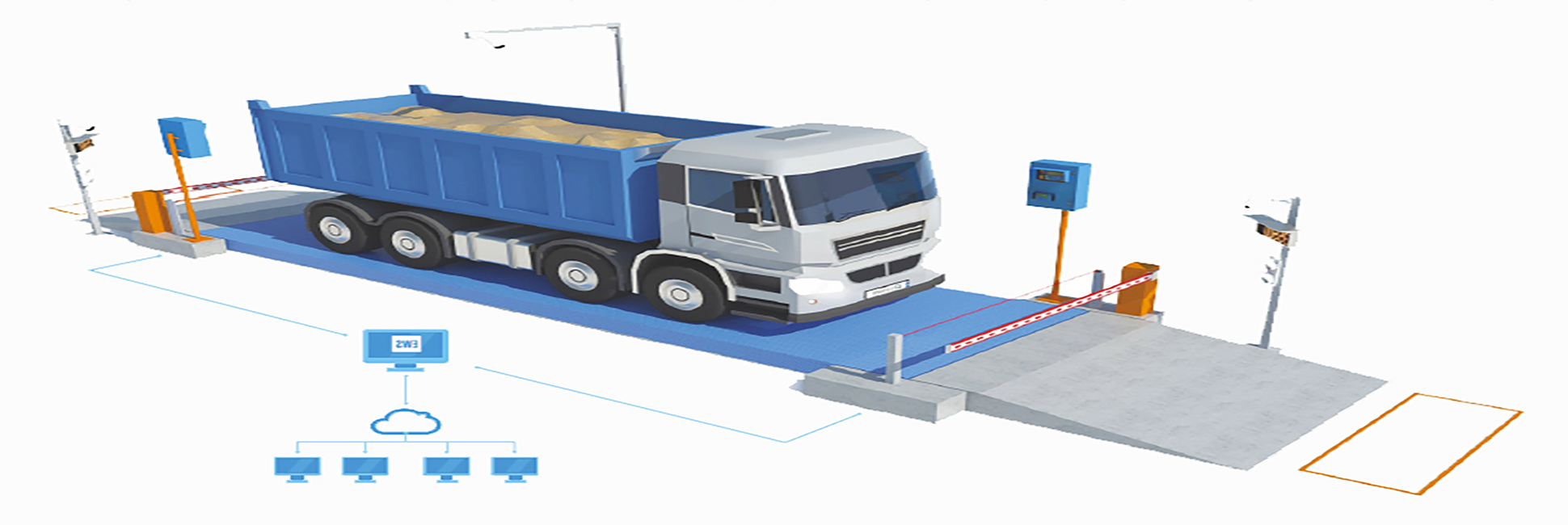

Pit Mounted

WeighBridge

Our weighbridge deck offers higher strength, greater reliability and faster installation suitable where there is space limitation. In pit mounted weighbridge the entire deck will be flushed with ground level. Major steel structural and load cells are not visible. Pit type weighbridges needs very less area compared to surface mounted weighbridge due to absence of ramps.

features :

- High strength reinforced mild steel weighbridge structure

- Designed for heavy weighment & harsh environment

- Each & Every parts are dismantle for easy transportation and installation

- Load cell assembly is designed and manufactured very precisely to absorb excessive impact force caused when vehicle enters & leaves the weighbridge

- All load cells are mounted on mounting assembly for better accuracy and repeatability

- Ramps not required hence can be constructed in less space

- Deck installed at ground level hence vehicle can easily enter and leave weighbridge

- Ribs are weilded continuously which ensures high transom strength.

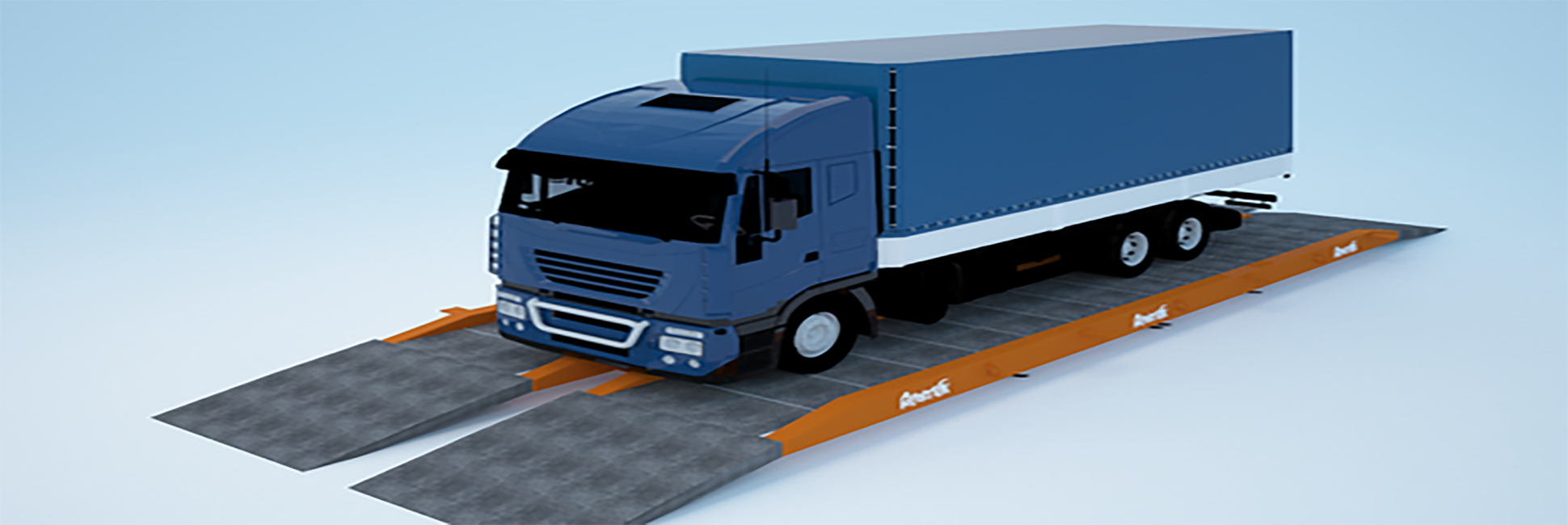

Modular

WeighBridge

Modular platform supplied with bottom frame and prefabricated ramps. It helps in cost-effective transportation and re-installation, needs no foundation or pit, just needs a hard and plain surface to rest load cell plates. It can be installed in a few hours compare to taking a couple of days of installing a surface or pit mounted weighbridge. It is suitable for temporary sites.

features :

- No special foundation required hence reduces civil engineering cost

- Designed for heavy weighment & harsh environment

- Fitted on simplified RCC platform or on strong road

- Can be placed directly in the wheel path of vehicle

- Being very low module height, it enables to use very short access ramps

- Rugged structure, but still be implemented flexibly

- Easy access for maintenance and cleaning due to centre opening along with entire length of the weighbridge.

- Ribs are welded continuously across I-beam which ensures extra strength to weighbridge deck.

Surface Mounted

WeighBridge

The sturdy and strong mild steel platform suitable where excavation work for foundation is difficult or construction of pit is expensive, easy in maintenance as platform is completely flushed above ground level, so no high water table or drainage problem. Approach by low angle ramps on both sides of weighbridge.

features :

- High strength reinforced mild steel weighbridge structure

- Designed for heavy weighment & harsh environment

- Each & Every parts are dismantle for easy transportation and installation

- Load cell assembly is designed and manufactured very precisely to absorb excessive impact force caused when vehicle enters & leave the weighbridge

- All load cells are mounted on mounting assembly for better accuracy and repeatability

- Less Expensive due to less civil construction required then Pit mounted weighbridge

- Economically and easily maintained and service as entire deck is mounted above the ground level

- Ribs are weilded continuously across I-beam which ensures extra strength to weighbridge deck.

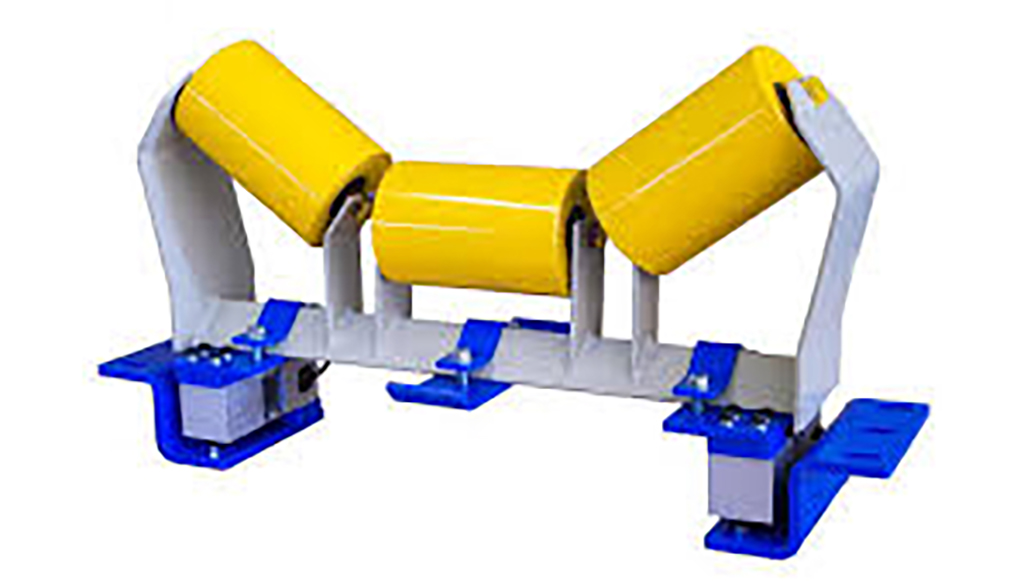

Belt Weighing

System

Belt scales or weight o meter are accepted means of moving bulk materials in process industries. With the advent of this fast mode of transportation, accounting the quantity of material transferred assumes great importance. Since weight remains as the most reliable index of material accounting and can be measured directly and precisely, designers can offer accurate weighing systems to maintain higher accuracy and better accountability in the process. Belt weighers also known as belt weighing scales are equipments that measures the quantity of material that has been conveyed by a belt.

features :

- The system uses straingauge type precision loadcell which have negligible deflection hence higher accuracy is achieved.

- Single idler with counter balancing arrangement for low belt loads having 2 loadcells and 4 loadcell platform type arrangement for high belt loads.

- Two idlers are used (using 4 loadcells) for weighing hence high resolution with respect to dead load of the belt and idlers.

- No mechanical levers are used to sense the belt load. Hence, no inaccuracy on that account.

- Digital Proximity speed sensor designed to generate sufficient pulses even at very low belt speed.

- High Speed ADC is used to have faster response.

- Self diagnostic facilities.

- Unique zero tracking software to compensate for varying “weight of the belt”.

- MODBUS/ Profibus/ remote display – communication port available as an option.

- Approved by weights & Measures.